Product category:

Ultrasonic Micro-Moulding - Moulds fine geometries in low-cost moulds

This micro-moulding process uses ultrasonic waves, instead of a screw and a heated barrel, to melt the plastic material before it is injected into the mould. The ultrasonic waves lower the viscosity of the melted polymer which then fills thinner geometries with a much lower injection pressure. The machine heats only the amount of plastic needed for each mould cycle so you can mould small quantities, or change the material, with little material waste.

Used for:

It is used to mould components for hearing aids, implantable devices, and other micro-mechanical systems.

Details:

The process can reduce energy consumption up to 90 percent compared with standard injection moulding. The maximum shot size is under two grams.

Idea:

Use the process to quickly test different materials with low-cost tools during product development.

The sample:

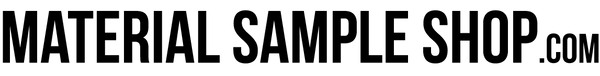

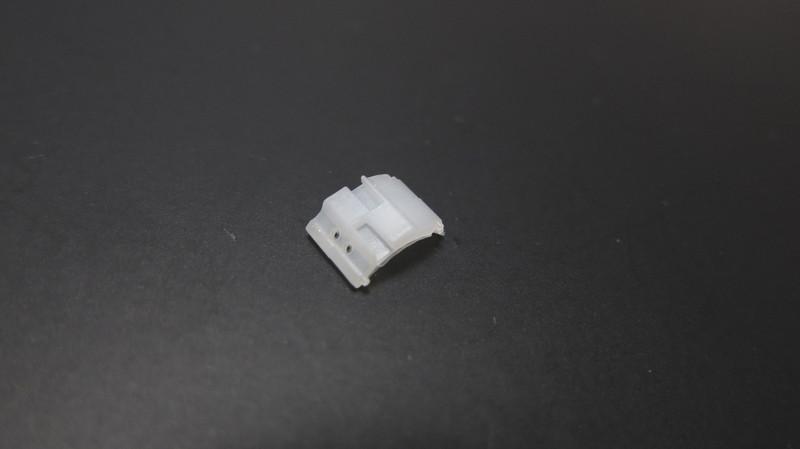

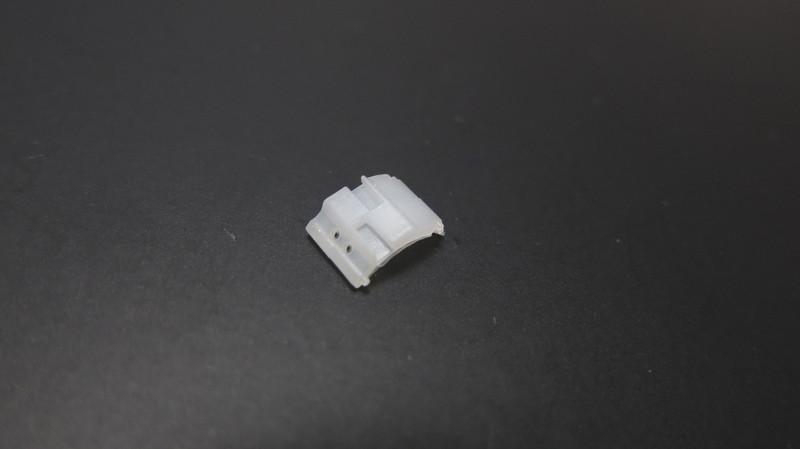

You get the small moulded sample seen on the picture.

All samples come with a laminated information card, which includes contact details for the supplier.

Ultrasonic Micro-Moulding - Moulds fine geometries in low-cost moulds is backordered and will ship as soon as it is back in stock.

The sample you get:

Estimate the shipping cost

Questions & Answers

Have a Question?

Be the first to ask a question about this.

Your payment is processed by Shopify or Paypal - We do not receive or have access to your credit card information.