Product category: Process

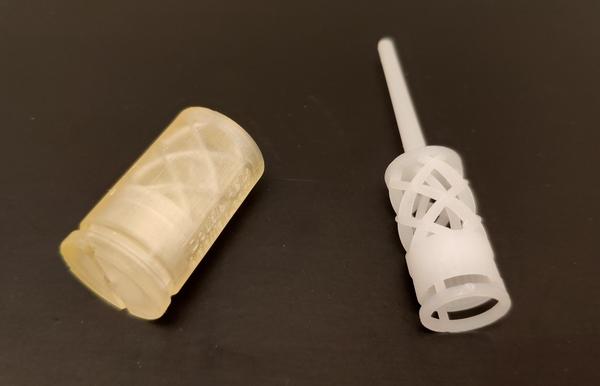

Freeform Injection Moulding (FIM)

Plastic injection moulding in 3D printed dissolvable moulds.

Applications for freeform injection moulding:

It is used to mould components for prototypes and low-volume production in a wide range of plastics that are rarely available for direct 3D printing. It can be used to mould components for product validation in the final production material before investing in hard tooling. It also allows for mass customisation of moulded plastic parts.

Idea:

Use it to quickly make out-of-stock spare parts.

Freeform Injection Moulding (FIM) is backordered and will ship as soon as it is back in stock.

The sample you get:

Estimate the shipping cost

Questions & Answers

Have a Question?

Be the first to ask a question about this.

Your payment is processed by Shopify or Paypal - We do not receive or have access to your credit card information.